Roller chains / Sprockets for roller chains

Roller chains / Sprockets for roller chains

Chains and sprockets are positive-locked drive elements, usually made of steel. They transmit high torques without slip and have a very long service life when correctly handled and maintained. We supply the most popular sprockets, chains, sprocket sets, chain tensioners and gliders as well as straight and cranked links from our warehouse.

Further information about our roller chains and sprockets for roller chains:

The most common material is standard or stainless steel (INOX). Our chains are manufactured to DIN 8187-1 / ISO 606 for European designs or to DIN 8188-1 / ISO 606 for American designs. Also available from stock are heavy-duty designs with reinforced flaps and enlarged joint surfaces, chain tensioners and chain gliders.

Benefits of chain drives: They provide slip-free power transmission. Relatively small wrap angles can be achieved thanks to the chain links. They are not usually susceptible to temperature fluctuations. Chains can be shortened or lengthened easily. We supply single straight or cranked connecting links. The roller chain features a number of advantages over other mechanical drive elements. The wide performance range due to the variety of chain sizes, single and multiple strand chains (simplex, duplex or triplex) and different materials, allow them to be used in a wide variety of environments

In very dirty environments, chain drives should be protected, as friction against stones or sand, for example in stone crushers, will greatly impair the sprocket and then of course the chain itself. With proper handling, chain drives will usually have an extremely long service life.

Lubrication: Good, regular lubrication is essential. We are able to offer a suitable program that ensures permanent lubrication and therefore the longest possible service life of your chain - even in hard-to-reach places.

The first English patent for a roller chain was granted in 1880 to a certain Hans Renold. Born in 1852 in Aarau (Switzerland), he studied mechanical engineering at the Polytechnical College in Zurich. His studies led him via Paris to England, where he soon began producing machine drive chains for the flourishing textile industry in his own small factory. Thanks to its precision, the «Renold chain» was a resounding success and also contributed to the spread of the bicycle industry. In agriculture, mining, and industrial manufacturing, the use of a reliable drive chain fulfilled exactly the need to transmit high loads at low speeds. Since then, the number of chain and sprocket producers has grown considerably across the globe.

Our own workshop:

Special operating sites sometimes require special adjustments: hardened teeth (inductive or flame hardened) or bore diameters that cannot be managed with normal clamping bushes - no problem! We can have various post-processing operations performed, either in our own workshop or by our long-standing partners. Contact us with your enquiry!

Roller chains Simplex - European design

Select a product group:

European design to DIN 8187-1 / ISO 606

- standard, type 04B1 | 05B1 | 06B1 | 08B1 | 10B1 | 12B1 | 16B1 | 20B1 | 24B1 | 28B1 | 32B1 | 40B1 | 48B1 | 56B1 | 64B1 | 72B1

- INOX (stainless), type 06B1 | 08B1 | 10B1 | 12B1 | 16B1

- reinforced version, type 08BH1 | 10BH1 | 12BH1 | 16BH1

Roller chains Duplex - European design

Select a product group:

European design to DIN 8187-1 / ISO 606

- type 06B2 | 08B2 | 10B2 | 12B2 | 16B2 | 20B2 | 24B2 | 28B2 | 32B2 | 40B2 | 48B2 | 56B2 | 64B2 | 72B2

Roller chains Triplex - European design

Select a product group:

European design to DIN 8187-1 / ISO 606

- type 06B3 | 08B3 | 10B3 | 12B3 | 16B3 | 20B3 | 24B3 | 28B3 | 32B3 | 40B3 | 48B3 | 56B3 | 64B3 | 72B3

Roller chains Simplex - American design

Select a product group:

American design to DIN 8188-1 / ISO 606

- standard, type 08A1 | 10A1 | 12A1 | 16A1 | 20A1 | 24A1 | 28A1 | 32A1

- reinforced version, type 10AH1 | 12AH1 | 16AH1 | 20AH1

Connecting links

Select a product group:

- type 04B1– 56B1 straight or cranked

- type 06B2– 56B2 straight, cranked up to type 48B2

- type 06B3– 32B3 straight or cranked

- type 06B1– 16B1 stainless INOX

- type 08BH1 – 16BH1 reinforced

- type 08A1 – 32A1 straight or cranked

- type 10AH1 / 50H1 – 20AH1 / 100H1 reinforced

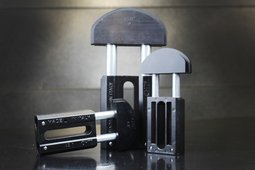

Sprockets Taper version

Select a product group:

sprockets Taper version

- pitch 06B = 3/8" x 7/32"

- pitch 08B = 1/2" x 5/16"

- pitch 10B = 5/8" x 3/8"

- pitch 12B = 3/4" x 7/16"

- pitch 16B = 1" x 17,02 mm

- pitch 20B = 11/4" x 3/4"

- pitch 24B = 11/2" x 1"

- pitch 28B-1 = 13/4" x 11/4"

- pitch 32B-1 = 2" x 11/4"

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

Our steel sprockets form the most important link between the chain and drive. We supply standard sprockets with a unilaterally protruding hub, pre-bored or as a Taper version with a normal or double taper. Certain sizes are also available as a Taper version with hardened teeth. The sprocket is determined by the chain size, in other words the pitch and version (simplex, duplex or triplex) and the number of teeth. When designing the chain drive, make sure that there is an odd number of teeth and links. This causes the teeth to engage alternately, ensuring optimal wear on the roller chain and the sprocket.

Sprockets standard version

Select a product group:

sprockets pre-bored with hub

- pitch 04B = 6 x 2.8 mm

- pitch 06B = 3/8" x 7/32"

- pitch 08B = 1/2" x 5/16"

- pitch 10B = 5/8" x 3/8"

- pitch 12B = 3/4" x 7/16"

- pitch 16B = 1" x 17,02 mm

- pitch 20B = 11/4" x 3/4"

- pitch 24B = 11/2" x 1"

- pitch 32B = 2" x 11/4"

All technical files to be downloaded have been checked with the utmost diligence. Nevertheless, we cannot guarantee the accuracy and conformity to our stock products.

Our steel sprockets form the most important link between the chain and drive. We supply standard sprockets with a unilaterally protruding hub, pre-bored or as a Taper version with a normal or double Taper. Certain sizes are also available as a taper version with hardened teeth. The sprocket is determined by the chain size, in other words the pitch and version (simplex, duplex or triplex) and the number of teeth. When designing the chain drive, make sure that there is an odd number of teeth and links. This causes the teeth to engage alternately, ensuring optimal wear on the roller chain and the sprocket.

Sprocket sets

Select a product group:

Simplex, Duplex, Triplex (simple, double, triple)

pitch 3/8“ x 7/32“ to 11/2“ x 1“

Chain sliders / Chain tensioners

Select a product group:

- chain sliders type CRS 3/8“ – 3/4“

- automatic chain tensioners

to complement our chains to DIN 8187-1 of the types

- Simplex 06B | 08B | 10B | 12B | 16B | 20B | 24B | 28B | 32B

- Duplex and Triplex 06B | 08B | 10B | 12B | 16B | 20B | 24B