Timing belts / Clamping plates

Timing belts / Clamping plates

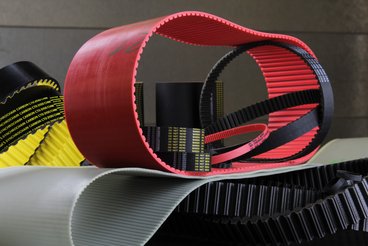

Modern timing belts consist of a tension member, teeth, a back and a protective fabric. They are characterised by their tooth shape, profile, pitch, the materials used and the construction and material of the tension members. We stock a wide range of the most commercially available timing belts from rubber or polyurethane, manufactured endless or by the meter. In our own workshop we can weld the polyurethane meter material to the desired length. Ex stock you also receive aluminium clamping plates.

Further information about our timing belts and clamping plates:

Toothed belt or timing belt is a collective term for drive belts that positively transmit torques in mechanical drive systems. Timing belts combine the benefits of a rubber belt with those of a chain. Continuous development of the materials used, the gear geometries and the manufacturing process results in significantly improved performance and increasingly better behaviour during operation of the gears.

We differentiate between traditional belts with a trapezoidal tooth profile and high performance timing belts either with an arched tooth profile (HTD®, STD® and CTD), an optimized trapezoidal AT profile or an arrow interlocked profile called HOT Helical Offset Tooth design. The trapezoidal teeth fit into the tooth gaps of the corresponding profile pulley without friction. Better quality materials are used for the tension members in high performance timing belts. The teeth are larger and have a wider tooth base. This improves engagement behaviour and reduces noise emissions. One major difference is in the manufacturing process. The rubber or chloroprene (CR) belts are made of synthetic rubber and are vulcanised, while the abrasion-resistant polyurethane (PU) timing belts with tension members made (mostly) of steel cord are cast.

Positive-locking synchromesh transmission was also introduced in the early 20th century alongside the existing belt drives. The first tooth profile, as we know it today, was developed in the USA by L.H. Gilmer. The first printed toothed belt catalogue appeared as early as 1949!

Gilmer recognised the gap between drive systems with rubber belts and those with chain drives. Timing belts offered the following advantages over V-belts and chains:

- low-noise

- no lubrication required

- higher power transmission due to the positive gearing

- higher rotational speeds

- negligible linear expansion

- smaller installation dimensions

- tighter wrap angles

A great deal of research was required to achieve the variety of timing belt profiles, grades and dimensions that exist today. The stringent requirements of a wide range of drive systems have be taken into consideration. Ever greater power levels have to be transmitted, the belts have to be in use for longer, even in the harshest of environments, in ever narrower spatial conditions, run even more quietly, be more resistant to an increasing range of materials and influences - meanwhile there is a drive belt for almost every requirement.

Of fundamental importance for the operating characteristics of the various timing belts are the producers' manufacturing processes and manufacturing technologies. We are a Swiss representatives for ContiTech Antriebssysteme GmbH (www.contitech.de). We also work with several European and Asian suppliers who supply us with some well-known branded products.

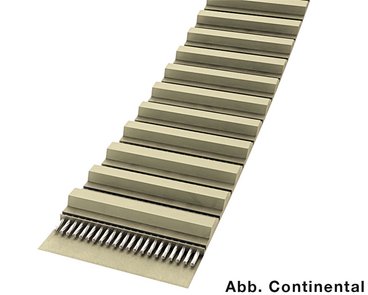

Traditional timing belts - rubber

with a trapezoidal profile, unilaterally toothed

- profile MXL - 2,032 mm | XL - 5,08 mm | L - 9,525 mm | H - 12,7 mm | XH - 22,225 mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

Traditional double timing belts - rubber

with a trapezoidal profile, double timing belt (teeth face each other without any offset)

- profile D/XL - 5,08 mm | D/L - 9,525 mm | D/H - 12,7 mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

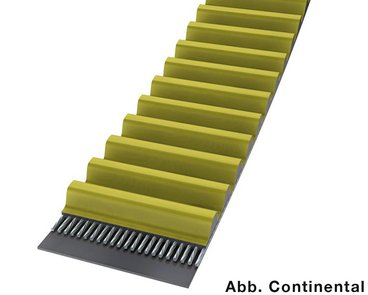

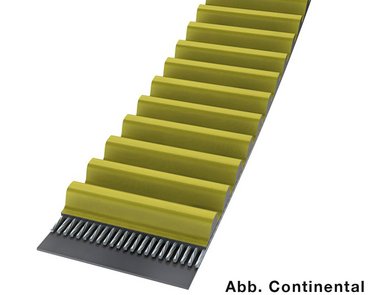

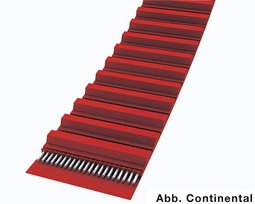

CONTI®SILENTSYNC - high performance timing belts

with an arrow interlocked profile

Design HOT (Helical Offset Tooth)

- CONTI®SILENTSYNC profile HOT 8 – types Y (yellow) | W (white) | P (purple)

- CONTI®SILENTSYNC profile HOT 14 – types B (blue) | G (green) | O (orange) | R (red)

Conti® SilentSync timing belts (formerly known as Goodyear Eagle NRG) have an arrow interlocked profile called HOT Helical Offset Tooth design. This HOT profile delivers an operational smoothness unrivaled by other timing belts, a reduced noise level and lower vibrations.

HTD® - timing belts - rubber

with an arched tooth profile, unilaterally toothed

- profile 3M - 3 mm | 5M - 5 mm | 8M - 8 mm | 14M - 14 mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

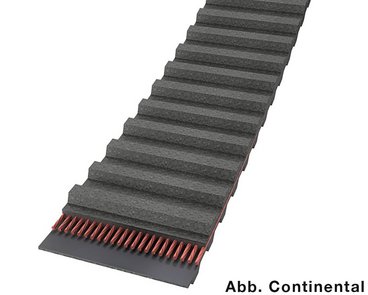

HTD® SYNCHROFORCE® CXP and CXA - high performance timing belts - rubber

with an arched tooth profile, unilaterally toothed

- SYNCHROFORCE® CXP, profile 5M - 5 mm | 8M - 8 mm | 14M - 14 mm

- SYNCHROFORCE® CXA, profile 8M - 8 mm | 14M - 14 mm (on request)

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

HTD® - double timing belts - rubber

with an arched tooth profile, HTD® - double timing belt

- profile D/5M - 5 mm | D/8M - 8 mm | D/14M - 14 mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

STD® - timing belts - rubber

with a parabolic profile, unilaterally toothed

- profile S3M - 3mm | S5M - 5mm | S8M - 8mm | S14M - 14mm

with a parabolic profile, double timing belt

- profile D/S3M - 3mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

STD® SYNCHROFORCE® CXP and CXA - high performance timing belts - rubber

with a parabolic profile, unilaterally toothed

- SYNCHROFORCE® CXP, profile S8M - 8mm

- SYNCHROFORCE® CXA, profile S8M - 8mm

Rubber timing belts have a strong tension member made of fibre glass, polyester or aramid and a back and teeth made of high-grade rubber. The entire timing belt is vulcanised to form a single unit.

T and AT - flex belts - polyurethane

Select a product group:

with a trapezoidal profile, unilaterally toothed

- standard flex belt, profile T5 - 5 mm | T10 - 10 mm

- standard flex belt, profile AT5 - 5 mm | AT10 - 10 mm

Polyurethane timing belts have a tension member made of steel, aramid or even carbon.

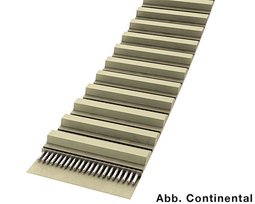

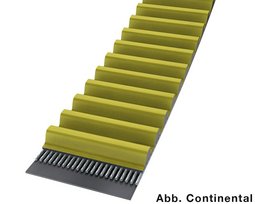

AT GEN III - timing belts - polyurethane

Select a product group:

with a trapezoidal profile, unilaterally toothed

- profile AT3 - 3 mm| AT5 - 5 mm | AT10 - 10 mm | AT20 - 20 mm (on request)

Polyurethane timing belts have a tension member made of steel, aramid or even carbon. These belts are cast in a mould.

CTD® SYNCHROCHAIN® - high performance timing belts - polyurethane

Select a product group:

CTD® SynchroChain / PolyChain - profile

- SYNCHROCHAIN® CTD, profile 8M | 14M with an aramid tension member

- SYNCHROCHAIN® CTD, profile 8M | 14M with a carbon tension member

Polyurethane timing belts have a tension member made of steel, aramid or even carbon. These belts are cast in a mould.

Clamping plates made of aluminium

Select a product group:

for linear drives which do not need welding

- profile XL | L | H | 5M | 8M | 14M | T5 | T10 | AT5 | AT10

- profile QST 8M | 14M (for timing belt Conti®SilentSync)